250Kg/H PE PP Film Plastic Granulator Machine Plastic Recycling Machinery

Product Details:

| Place of Origin: | CHINA |

| Brand Name: | JIN MACHINE |

| Certification: | CE Certificate |

| Model Number: | JIN-75 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Standard wooden frame and wooden case is available for Jin Machine Excellent Rigid Packaging drying dryer for plastic recycling |

| Delivery Time: | 45 work days |

| Payment Terms: | T/T, L/C, D/A, D/P, Western Union, MoneyGram |

| Supply Ability: | 10 sets per month |

|

Detail Information |

|||

| Application: | PET Granulating | Capacity: | 250 Kg/h |

|---|---|---|---|

| Material: | 304 Stainless Steel | Raw Material: | PET Flakes Or Bottles |

| Motor: | Siemens Brand | Warranty: | 12 Months |

| Production Period: | 55 Days | ||

| High Light: | 250Kg/H Plastic Granulator Machine,PP Film Plastic Granulator Machine,250Kg/H Plastic Recycling Machinery |

||

Product Description

250Kg/H PE PP Film Plastic Granulator Machine Plastic Recycling Machinery

250Kg/h PE PP Film Recycling Granulator Plastic Granulating Machine

1. Description:

Double stage pelletizing line is especially good for the raw material which contain high moisture, high impurities.

The first stage extruder adopts exhaust type barrel screw, which can effectively de-gassing and eliminate the moisture and contamination;

And the second extruder usually adopts small L/D extruder, further plasticizing the material and filter contamination which can achieve stable extrusion.

2. Detailed description of each items:

1. Conveyor: convey PP PE film or flakes into compactor.

2. PE film Agglomerator /Compactor: crushing and compress film, and feed compressed film into extruder forced, to make the production capacity high and stable.

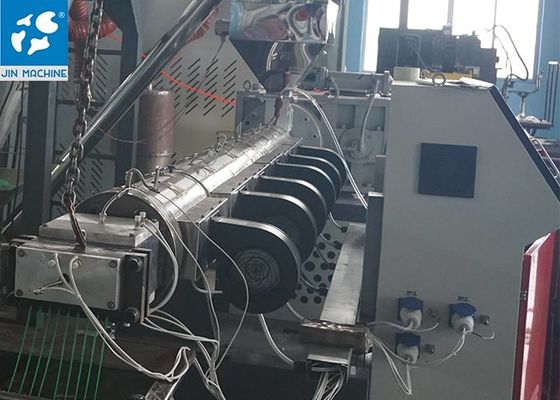

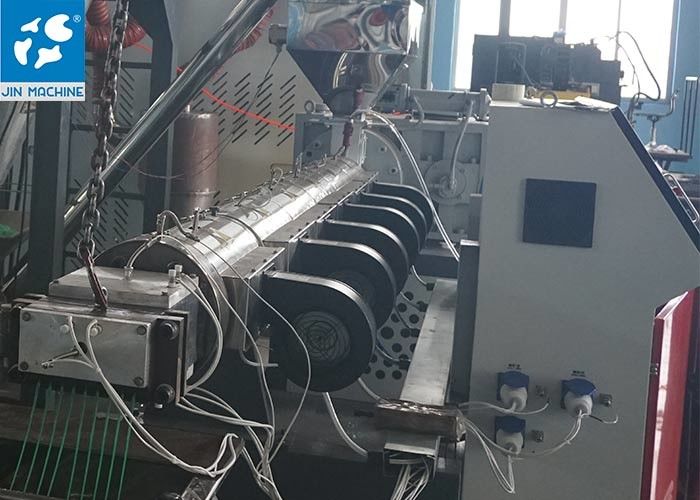

3. 1# Extruding system: plasticizing material and exhausting gas.

4. 1# High speed Net exchanging system: filter material impurity, to make production more stable.

5. 2# Extruding system: plasticizing material.

6. 2# High speed Net exchanging system and Die-head: Second filter material impurity, to make production more stable.

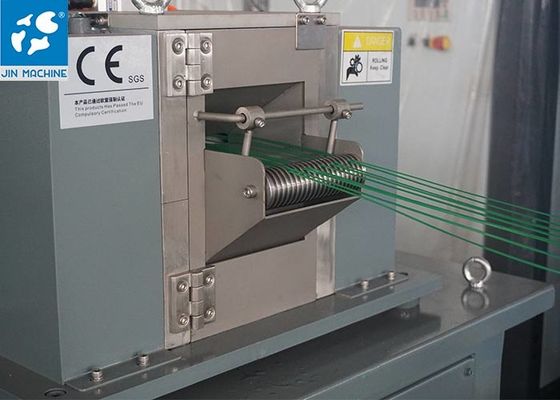

7. water ring pelletizing machine: cutting pellets in water.

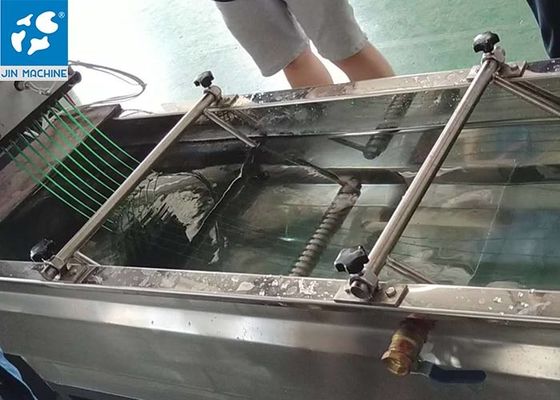

8. Water tank: cooling pellets.

9. Dewater machine: make pellets dry.

10. Vibration sieve: remove bad pellet and keep good pellet.

11. Air Blower: convey good pellets into silo.

12: Storage silo: keep pellet.

3. Equipment List:

| 1 | Belt conveyer (can equip the metal detector ) |

| 2 | Agglomerator /Compactor machine |

| 3 | 1# Extruder |

| 4 | 1# Die head and screen changing device |

| 5 | 2# Extruder |

| 6 | 2# Die head and screen changing device |

| 7 | Water ring cutter |

| 8 | Vibrating screen |

| 9 | Vertical dewatering machine |

5. Features :

1. Allow free assembling of the screw component, based on raw material type.

2. Using the suitable die head for palletizing, such as water ring cutting, under-water cutting and hot face cutting.

3. High efficient force feeder ensures stable high capacity material feeding, low power consumption.

4. Main screw has vacuum exhaustion.

5. Water ring granulator machine, attached with dryer. 6. Single screw extruder, with specially designed screw, barrel, venting system, ensure the good quality of the final products.

7. Parameter

| Model | PNHS-85/85 | PNHS-100/100 | PNHS-130/130 | PNHS-180/180 |

| Screw Dia. (mm) | 85 | 100 | 130 | 180 |

| L/D | 25-36 | 25-36 | 25-33 | 25-33 |

| Capacity (kg/h) | 120-180 | 200-250 | 400-500 | 500-1000 |

![]()