High Output 200kg/H SS304 PET Plastic Recycling Granulator Machine

Product Details:

| Place of Origin: | CHINA |

| Brand Name: | JIN MACHINE |

| Certification: | CE Certificate |

| Model Number: | JIN-75A |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Standard wooden frame and wooden case is available for Jin Machine Excellent Rigid Packaging drying dryer for plastic recycling |

| Delivery Time: | 45 work days |

| Payment Terms: | T/T, L/C, D/A, D/P, Western Union, MoneyGram |

| Supply Ability: | 10 sets per month |

|

Detail Information |

|||

| Application: | PET Granulating | Material: | 304 Stainless Steel |

|---|---|---|---|

| Raw Material: | PET Flakes Or Bottles | Motor: | Siemens Brand |

| Warranty: | 12 Months | Production Period: | 55 Days |

| Capacity: | 200kg/h | ||

| High Light: | High Output Plastic Recycling Granulator Machine,SS304 Plastic Recycling Granulator Machine,200kg/H Plastic Recycling Granulator Machine |

||

Product Description

High Output 200kg/H SS304 PET Plastic Recycling Granulator Machine

200kg / H PET Granulating Machine , Plastic Granulating Line 304 Stainless Steel

1. Application:

Widely used in waste plastic recycling, depending on material characteristics, including for LLDPE/LDPE/HDPE/PE/EPE film, pulverized material, lithium battery film, foamed pearl cotton, PP/OPP/BOPP/CPP film, woven bag, no Textile (meltblown), PA66 fishing net, silk, factory edge material, PET/BOPET bottle, film, silk, waste cloth head, foam, PTT filament, EPS/XPS crushed material, cold pressed foam, hot melt foam, Insulation board, HIPS/PC/ABS appliance housing, electronic waste, factory plastic, PVB pulverized material, PU and other unfinished materials are recycled and reused, requiring high-volume forced feeding into the single/double-screw granulating production line to meet Customer production needs.

2. Equipment is customized according to customer requirements

According to the type of material, it can be equipped with compaction recovery granulating production line, double-stage recycling granulating production line, double-screw recycling granulating production line, pelleting method can be equipped with water ring cutting, water cooling strip or underwater pelleting.

3. Configuration(according to your requirements)

| NO. | Description of goods | Total Power Consumption | Quantity |

| 1 | Screw Feeder ( Convey to 3000L Drying Hooper) | 1.5 kw | 1 |

| 2 | CSG 3000 Dehumidifying Dryer | 96 kw | 1 |

| 3 | Screw Feeder (Convey to SJ100 Extruder) |

1.5 kw | 1 |

| 4 | SJ 120 Single Screw Extruder | 135 kw | 1 |

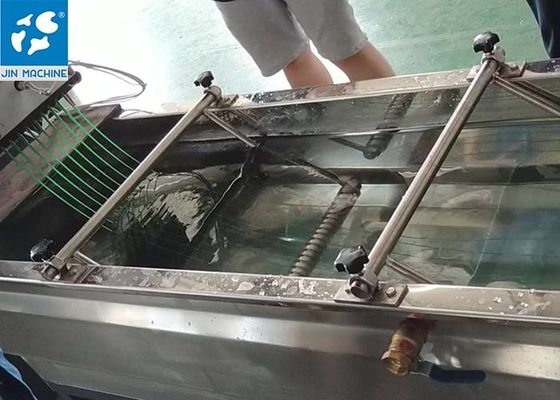

| 5 | Cooling bath | - | 1 |

| 6 | Air Dryer | 1.5 kw | 1 |

| 7 | Pelletizer | 5.5 kw | 1 |

| 8 | Vibrating Screen | 0.25 kw x 2 | 1 |

| 9 | Crystallizer | 35.5 kw | 1 |

| Total | 277 kw | ||

![]()