Low Energy Consumption 250KG/H PP PE Plastic Granulator Machine

Product Details:

| Place of Origin: | CHINA |

| Brand Name: | JIN MACHINE |

| Certification: | CE Certificate |

| Model Number: | JIN-75 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Standard wooden frame and wooden case is available for Jin Machine Excellent Rigid Packaging drying dryer for plastic recycling |

| Delivery Time: | 45 work days |

| Payment Terms: | T/T, L/C, D/A, D/P, Western Union, MoneyGram |

| Supply Ability: | 10 sets per month |

|

Detail Information |

|||

| Application: | PET Granulating | Material: | 304 Stainless Steel |

|---|---|---|---|

| Raw Material: | PET Flakes Or Bottles | Motor: | Siemens Brand |

| Warranty: | 12 Months | Production Period: | 55 Days |

| Capacity: | 250 Kg/h | ||

| High Light: | PE Plastic Granulator Machine,250KG/H Plastic Granulator Machine,Low Energy Consumption Plastic Granulator Machine |

||

Product Description

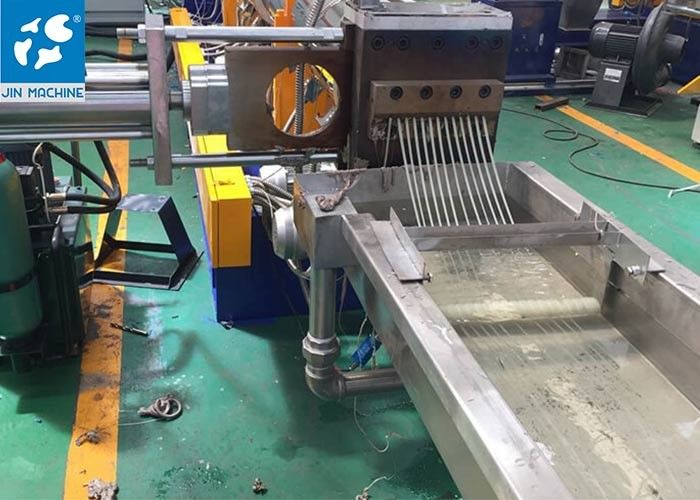

Low Energy Consumption 250KG/H PP PE Plastic Granulator Machine

Low energy consumption 250KG/H PP PE granulating machine plastic

1. Introduction of granulating machine

JIN series of twin screw extruder function and features: homogeneity,plastic coloring, filling modification, reinforcement, reclamation and pelletizing.

The screw adopts toy bricks design principle, the screw shape and the barrel structrue, raio of length and diameter, feeding device, screen changing and pelletizing method, electric control mothed all can be optimized and adjusted accroding to the material system and the technique requirements, to give consideration of the multi-function, multipurpose and special purpose, with the advantage of high capacity and low consumption

2. Characteristics of granulating machine:

- pelletizing without dust so there will not be the problem of strand broken.

- The granules are regular and full, no air hole,similar to the new raw material granules

- Customer can easily change the size and shape of the granules

- Pelletizing and cooling are integrate into one whole whicn reduced the machine ground covering square.

- With high automation and reduced the labor waste

- Comparing with other pelletizing way, the capacity is bigger and the die face can has 60-100 granules holes

3. Characteristics of Spare parts of water-ring granulating machine

A.the gear box

1)rotating speed:MAX 600~1500RPM

2)combining host transmission box speed reduction and torque distribution part together,using three axis style design, with compact structure. Speed reduction, torque distribution and two output shaft radia bearing all use NSK bearings.

3)Gear is 6 grade which is a high precision. High speed overloading hard-tooth surface.

The materials are 20CrNi2MoA or 20CrMnMo, HRC 60/62.

B.the feeding system

Various forms of feeding structure and system single screw extruder, twin screw, hollow spring type, mesh and mesh, can cover the various material status

C.screw and barrels

Screw Kneading block built on modular principle allows various L/D ratio of screw easily be changed to suit different material. Screw component made of high speed & wear-resisting steel.

The screw elements are designed accuratly and made of high tool steel 38CrMoALA or W6Mo5Cr4V2 by special heater treatment.

4. Why choose JIN MACHINE

With more than decades of practical experience, JIN MACHINE Co., Ltd. has been in the field of manufacturing extrusion machine. We strive to maintain the quality and customer satisfaction as they are our business objective.

| Advantages: |

|

|

|

|

|

|

![]()