250kg/H Bottle Flake Pet Strap Production Line single screw

Product Details:

| Place of Origin: | China |

| Brand Name: | JIN |

| Certification: | CE |

| Model Number: | JIN-SJPET-90 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | 70000$-170000$ |

| Packaging Details: | wraped with plastic film |

| Delivery Time: | 60dyas |

| Supply Ability: | 20per/month |

|

Detail Information |

|||

| Production Capacity: | 150-250kg/h | Installation: | L40000*W3000*H6500 (mm) |

|---|---|---|---|

| Thickness Range: | 0.5-1.5mm | Width Range: | 5-32mm |

| High Light: | -250kg/h pet strap production line,bottle flake pet strap manufacturing machine,bottle flake pet strap making machine |

||

Product Description

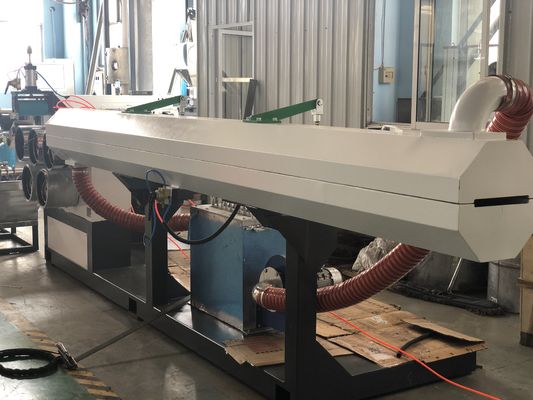

250kg/H Bottle Flake Pet Strap Production Line single screw

Product Description

Fully Auto Industrial PET Strapping Production Machine Line For Packing

PET plastic steel belt production line one out two product parameters:

Name: PET plastic steel belt production line

one out of two Model number: SJ90/33

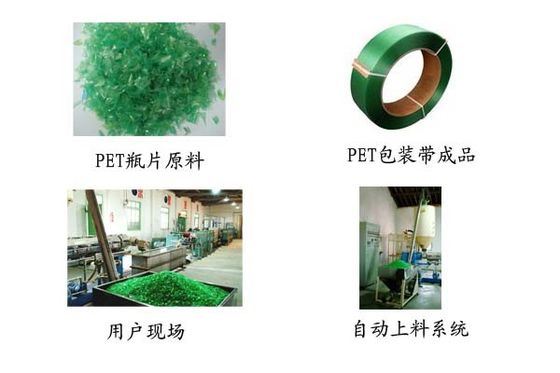

Applicable raw materials: bottle flake material, 100% broken material

Number of screws: 1

Screw size: Ø90

Number of extruded belts: 2

Width range: 5-32mm

Thickness range: 0.5-1.5mm

Production capacity: 150-250kg/h

Installation size: L40000*W3000*H6500 (mm)

As a new type of strapping product with strong tensile force and corrosion resistance, PET strapping belt is gradually replacing traditional stainless steel strapping products with overwhelming advantages in performance and price. Therefore, the potential of PET strapping production line as a small and medium-sized investment is huge.

The production line includes:

Baking machine (It is heated by heat-conducting oil, which is evenly heated without damaging materials.) Dehumidification and dry storage system (Advanced equipment technology, imitating honeycomb constant temperature and humidity technology, remove the molecular moisture of PET material.) Feeder (Adopt super strong magnet to absorb metal impurities to ensure the quality of strapping.) Extruder Cooling water tank Extension unit (Including thermal cycle constant temperature energy-saving oven and 5-roller traction, all adopt gear transmission form to ensure stable power.) Embossing setting unit (The cross-air cooling technology is adopted for rapid cooling and temperature reduction to ensure that the strapping belt is not cracked and has better toughness.) Winder (Each strap is equipped with a double-station winder, which is convenient for adopting and switching.)

The PET strapping belt production line is a complete set of equipment that uses PET waste mineral water, Sprite, Coke and other bottle flakes as raw materials to produce PET plastic-steel strapping products.

Features of PET plastic steel belt production line:

1. PET belt, also known as plastic steel belt, is a new type of strapping belt that is currently popular in the world instead of steel belt. It is widely used in steel, aluminum, chemical fiber, cotton spinning, tobacco, paper, metal can making and other industries.

![]()

![]()

![]()