double out put PET Strap Production Line

Product Details:

| Place of Origin: | CHINA |

| Brand Name: | JIN MACHINE |

| Certification: | CE;SGS;ISO9001 |

| Model Number: | JIN-SJPET200 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Standard wooden frame and wooden case is available for Jin Machine Excellent Rigid Packaging drying dryer for plastic recycling |

| Delivery Time: | 60 work days |

| Payment Terms: | T/T, L/C, D/A, D/P, Western Union, MoneyGram |

| Supply Ability: | 10 sets per month |

|

Detail Information |

|||

| Product Name: | PET Strap Production Line | Raw Material: | PET Flakes Or Granules |

|---|---|---|---|

| Capacity: | 200 Kg / H | Application: | Plastic Strap/band/packing |

| Material: | SUS 304 Stainless Steel | Warranty: | 12 Months |

| Power: | 250 | Motor: | Siemens Brand |

| Production Period: | 60 Days | ||

| High Light: | 400kg Plastic Strap Production Line,Corrosion Resistant Plastic Strap Production Line,400kg Plastic Strap Production |

||

Product Description

double out put PET Strap Production Line

200Kg Automatic PET Belt Production Line Siemens Control Easy Operation

1. Introduction for Jin Machine’s packing production line:

JIN Machine CO., Ltd. production of pet packing belt production line, is in Italy and Germany, the technical basis of equipment, combined with the actual use of customer experience development. Pet automatic machine with packing belt refers to the packing belt in the width error, thickness error, bending degree (straightness) error, etc. fully comply with the automatic packaging machine standards. and packaging bandwidth, thickness, bending (straightness) is proportional to the quality of production equipment.

2. Description of Pet Packing Belt production line:

Pet packing belt also known as plastic steel belt: is a new type of strapping belt, widely used in cotton spinning, chemical fiber, metallurgy, casting, canning, refractories, ceramics, brick, glass, paper, furniture, tobacco, wood, electronics and other industries.

3. Working flow for Packing Belt production:

First: Raw material mixture drying (pre-crystallization)

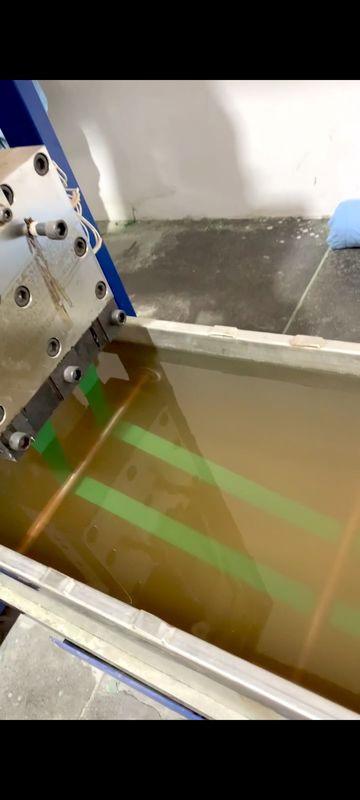

Second : extrusion heating-melting

Third: heating stretching molding

Fourth: rolling flower (not rolling flower

Fifith: annealing and cooling

Fifth.packing storage.

4. Main parameters:

| Name/Model | Host Model | Maximum output | Product Specifications | Straps | Production Energy Consumption |

| JIN-SJPET200 | SJPET200 | 200kg/h | 9-32mm | 2 | Approx. 250kw |